Solutions

A Market Leading Solution Provider

Our expert packaging process is the key to the reliability and functionality of semiconductor diode chips and without Coset’s proper designs, handling often fails. We are continually looking for ways to develop the most effective packaging environment for all of our products.

Working with our customers to achieve design targets, our experienced design and production teams create anything from industry standard to custom-designed semiconductor diode chips to our customers’ specifications.

Our company also partners with customers who have specialized manufacturing needs that their own facilities can not meet. We provide these partners with anything they need to help them deliver the desired high-quality products.

With 20 years of telecom device manufacturing we guarantee our quality control team will meet the rigorous standard required in our industry.

Our opto-electrical designing, coupled with dynamic creativity, is always aligned to our customer’s target needs and enables prompt proof design prototypes resulting in cost effective volume production of the final product.

Collaboration Process

1. Initial Designing

Working hand in hand with our customers, our professional design team ensures that our clients needs are met the second our partnership begins.

2. Spec Validation

Precise, exacting measurements and attention to detail at the outset of the manufacturing process is one of many steps in delivering a quality finished product.

3. Cost Validation

Our Korean-based cost-effectiveness with high quality sets us apart from the low-quality, slightly lower cost of China or much higher costs of Japanese industries.

4. Prototyping

Thanks to the attention to detail by our production and manufacturing teams, the prototypes guarantee the products we deliver will meet the stringent requirements needs of our clients.

5. Reliability Test

Our best in the business quality control process and reliability testing gives the client the peace of mind that their products will be manufactured to reach at a zero defect rate.

6. Mass Productions

Our state-of-the-art facilities are capable of manufacturing products at high-speeds with an output that will fill any customer order no matter how large with on-time delivery.

Portfolio

Pump Lasers

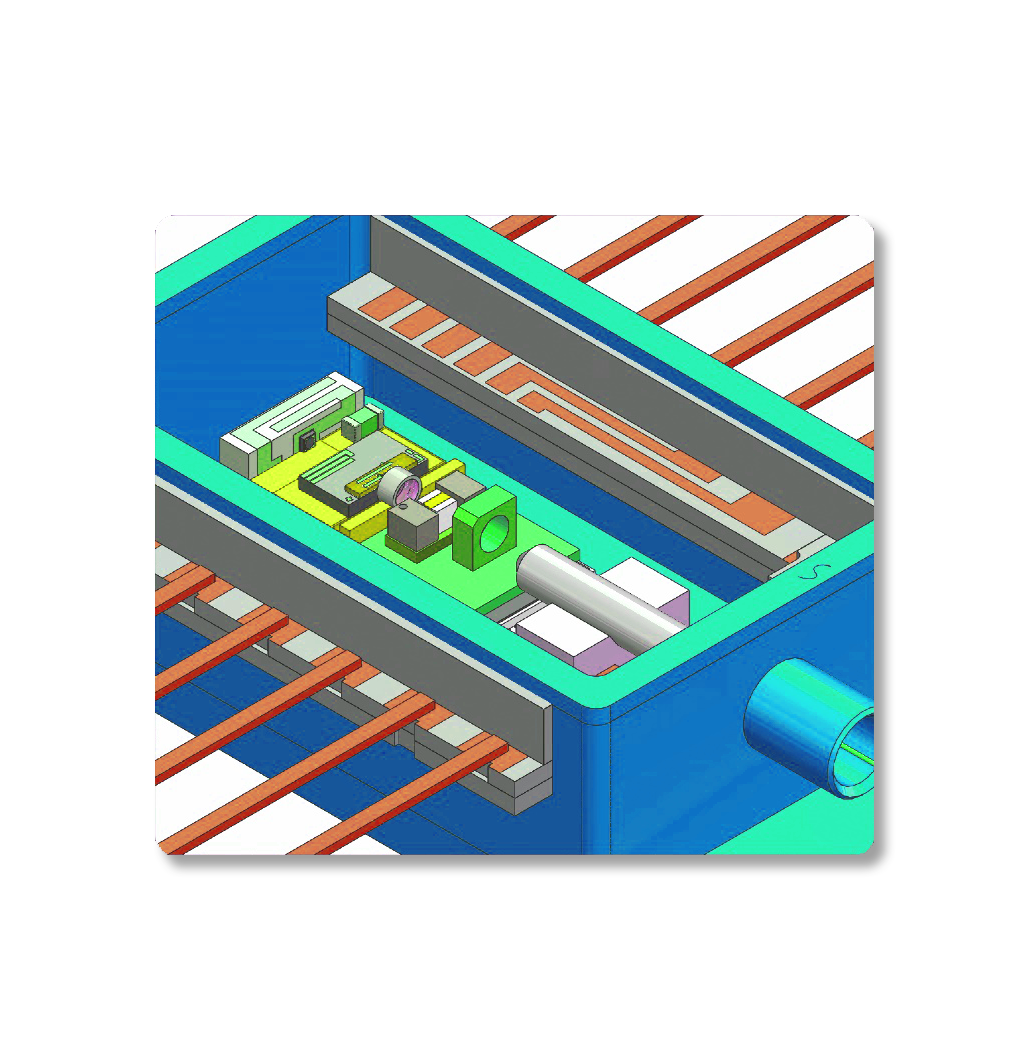

The pump laser is the core component of optical amplifiers. Coset began with 980nm pump laser packaging capability with the most rigorous telecom device reliability requirements of the Telcordia 468-CORE complied structure. A direct-coupling structured 980nm pump lasers in industry standard cooled 14pin butterfly and uncooled 8pin mini DIL package types are in pipe lines for volume production scale for laser diode chip customers globally.

SLEDs

A successful launching of direct coupling structured pump laser enabled Coset to extend packaging items to SLED (Super Luminescent Light Emitting Diode). Various wavelengths SLED chips on submount are packaged into cooled 14pin butterfly and 14pin DIL package types. A high-efficiency and reliable structure maximizes SLED performance and is used in various applications in the industry. Packaged SLED modules are used in telecom, medical, sensing, defense and security applications.

Industrial Lasers

A remarkable development was the achievement of high power multimode laser diode, which encouraged Coset to enter packaging opportunities of pigtailed pump lasers used for various industrial applications. Industry compatible packages with various core diameter multimode fiber provide sufficient high power output for pumping.

Special Custom Packaging

Coset also provides specialized packaging services for various customers with creative, unique design ideas. From electro-optical designing to hybrid structures, the Coset design team works with customers in order to meet their production needs. Integrated optic design of various prototype ideas has resulted in many functional products.